Woodworking craftsmanship is also about creating an exceptional product that makes a statement, is durable, and indulges in style.

Unique Custom Doors delivers on this promise through a combination of our experienced craftsman, technology, and design.

CRAFTMANSHIP

Preliminary design process

It all starts with the design concept. At Unique Custom Doors the design of your door is a personalized experience.

Although we welcome and appreciate all of our clients’ ideas, we can also provide one-on-one design recommendations.

Our creative and experienced personnel will be pleased to assist you with the style of your door to achieve harmony between your door and your residence.

Our goal with customization is to create a product that emanates exclusivity and style.

It is very important to be knowledgeable about the location and environment of where each unit is installed. Doors located facing SOUTH, WEST, or SOUTHWEST orientations are considered in critical zones. These critical zones will leave your door exposed to direct sunlight.

Talk to one of our representatives to advise you on what your options are if your door faces any of these directions.

craftmanship

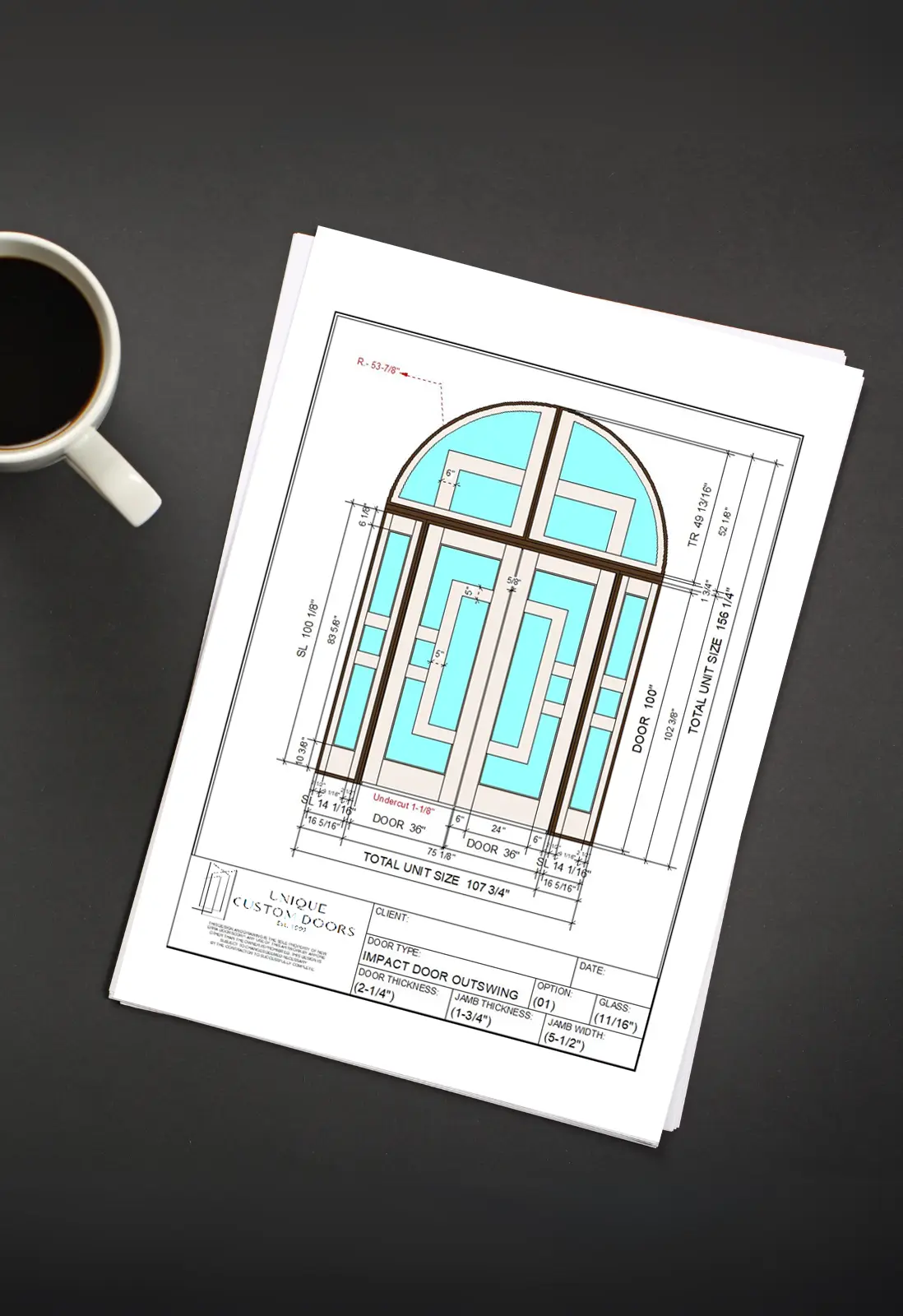

Shop drawings & Computer Aided Design (CAD)

Once we have preliminary measurements and a door style, the coordination of shop drawings begins.

Before we are able to provide our clients with a final design, our professionals perform a site observation where final measurements are taken, and the project is coordinated.

Then, the final CAD design comes into play.

This CAD will provide the client with the selected design and final measurements for the door to be manufactured.

Behind the final CAD design comes a strong effort of coordination with the owner, builder, and installer ensuring all the parties are in agreement.

CRAFTMANSHIP

Lumber selection

The production process starts with the lumber selection.

The exceptional beauty of wood products lies in the natural color of the lumber, the pattern and properties of the species.

Therefore, we ensure only the finest prime lumber is selected for our production.

Initially, the lumber is kiln dried to achieve the right moisture content.

Following, our quality control department takes special care to ensure only the best boards are selected which discards any possible defects in the production of our doors.

We primarily work with premium South American mahogany that has continuously proven to be the most durable and stable lumber to utilize in humid and temperature sensitive environments.

craftmanship

Product Manufacture

From start to finish, our skilled craftsmen deliver a product assembled and engineered to provide you a stable and durable door.

All styles and rails are carefully connected with specific wood joint systems. Implementing the use of wood joints between each component will highly reduce the probability of warping and splitting, compared to using one single wood piece and/or various other materials.

Then, the structurally engineered stiles and rails will conform to a solid and stable wood door. In contrast to conventional wood door manufacturers that adhere to a single standard door thickness, our approach involves working with various door thicknesses, ranging from 1 ¾” to 3”. This strategic flexibility allows us to tailor the door thickness to the structural requirements of the design and the dimensions of the unit.

After the door is assembled, it goes through a sanding process. This process provides a smooth to the touch and even surface all throughout the door.

CRAFTMANSHIP

Final Product

The door is ready for quality control and quality assurance.

Our QC/QA team vigorously checks that the doors were built to the correct measurements and safety standards.

Each door goes through a meticulous quality control process directed by three different professionals minimizing production error close to zero.

In this way we make sure our clients are getting the highest quality and most durable products in the market.